OneWaySpikes.com

Open weekdays 8 AM- 4PM

520-780-9751

Manually Operated Rising Barrier Gate Arm

MANUAL LIFT BARRIER GATE with ALUMINUM ARM

Affordable & Easy to Install

Control Your Vehicle Access Entries & Exits

Call (520)780-9751 or email [email protected] today for your price

Affordable & Easy to Install

Control Your Vehicle Access Entries & Exits

Call (520)780-9751 or email [email protected] today for your price

♦High Quality Steel Construction

♦Lightweight Aluminum Arm

♦Powder Coated Safety Red

♦Counter Balanced for Easy Lift - Non Adjustable

♦Red & White Reflective Striped Arm - MUTCD Compliant

♦Lockable in the Up or Down Position

♦Choice of Surface Mount Flange or In Ground

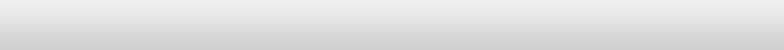

♦Choice of Resting Post or Pendulum Support Post

Double Swing Gate for extra wide road ways.

Heavy Duty Steel Construction (all welding by AWS Certified Welders)

Round Aluminum Arm is Powder Coated White and has an 11" Red / 7" White DOT-C2 ORALITE (Reflexite) Reflective Conspicuity Tape on both sides/full length of the barrier arm. 10 Year Tape

42" Tall

Standard Color is Safety Red. Other color choices are available for an affordable "upgrade fee"

Surface Mounted

15" X 15" X 3/8" Base plates - pre drilled for surface fixing

Barrier Arms are affordable and easily replaced. Just call, order and we will ship to you

Barrier Arms Longer than 12 feet - Arm Sections are Sleeved together with an Aluminum tube insert and secured with bolts, the sleeve is perfectly machined to fit snug so there is no movement within the sleeved arm sections and the barrier arm is the same diameter from end to end

♦High Quality Steel Construction

♦Powdered Coated Safety Red (custom colors available)

♦Lightweight Aluminum Arm - Powdered coated white

♦A 10 Year Red and White Reflective Conspicuity Tape on both sides/full length of the barrier arm for maximum visibility

♦Counter Balanced for Easy Lift - Adjustable counter weight

♦Quiet Stop Rubber Bumper System, bolts on and is easily replaced when needed

Cushions the stop when raising and when lowering the boom arm

♦Chemical and Weather Resistant Foam Rubber Grip Comfort Handle

♦Locking Hasp that accepts your padlock in both the Up and Down Position

Model SL-LB in a 12 ft, 16 ft, or 20 ft

Need a 12 footer? Maybe a 20 footer? How about a 30 footer?

We have you covered!!

Support Post, Pendulum Support required for arms over 16 feet

A Pendulum Support Post or a Tip Receiving Post is Required on barrier arms over 16 feet

Mounting Suggestions for the SL-LB Manual Lift Barrier Gate Arm

Please consult with an engineer for the best advice on mounting pads. As soil conditions are always different.

Surface mounted plate with 4 pre- drilled 5/8” diameter bolt holes. The mounting plate is 15” X 15” and 1” in from edges gives you center of the bolt holes.

Mount on to concrete or build a concrete pad and use four 1/2" diameter and 6" to 8" long concrete anchors. (j bolts, or LDT)

It needs to be mounted on to concrete or a concrete pad. Be sure that the concrete is cured before drilling the bolt holes in to it. Or pre- make the pad with anchor bolts.

A 16 X 16 is usually a sufficient size and should be 8" or better for the thickness. Use rebar too. 8 #4 rebar evenly spaced in every direction. Make sure concrete is 2" or more over the rebar. Use a 4 to 5000 psi concrete.

You can also opt to use a drop-in anchor so that you can easily unbolt from the pad and move the unit to another pad and back again. Such as, CONFAST® DropIn Anchors.

Or you can build portable pads that can be moved around by a fork lift.

Portable pad:

Should be at least 36” X 36” and 8” thick or more.

The slab would need a couple of 2” high by 8” wide slots in the slab for the fork lift forks.

4000 psi concrete should be used. 8 #4 rebar, 4 in each direction evenly spaced with a minimum of 2” of concrete over the rebar.

Wait at least 14 days for a cure time before drilling bolt holes or moving.